Tackling e-powertrain calibration complexity with advanced machine learning

Discover how Secondmind leverages machine learning to simplify e-powertrain calibration, enhancing e-motor efficiency & reducing development time. Award-winning tech for the electric vehicle industry.

In the competitive Electric Vehicle (EV) market, engineers must contend with the dual pressures of innovating, simulating, and testing robust e-powertrain solutions and accelerating production cycles to meet the global demand for sustainable transportation. The Secondmind for Calibration application for e-powertrain, recently awarded Alternative Powertrain Test Innovation of the Year at the 2024 Automotive Testing Technology International (ATTI) Awards, offers automotive Original Equipment Manufacturers (OEMs) a strategic edge by addressing these industry-wide issues to enhance e-motor efficiency and significantly reduce development time.

E-powertrain calibration complexity - the status quo

The e-motor and inverter pair are at the core of the e-powertrain system, and they present calibration challenges, such as rigorous thermal management and complex parameter interactions. Precise calibration is crucial for optimizing efficiency and vehicle range, requiring accurate and robust modeling to predict the impact of changes in parameters like current levels, energy consumption, and RPM.

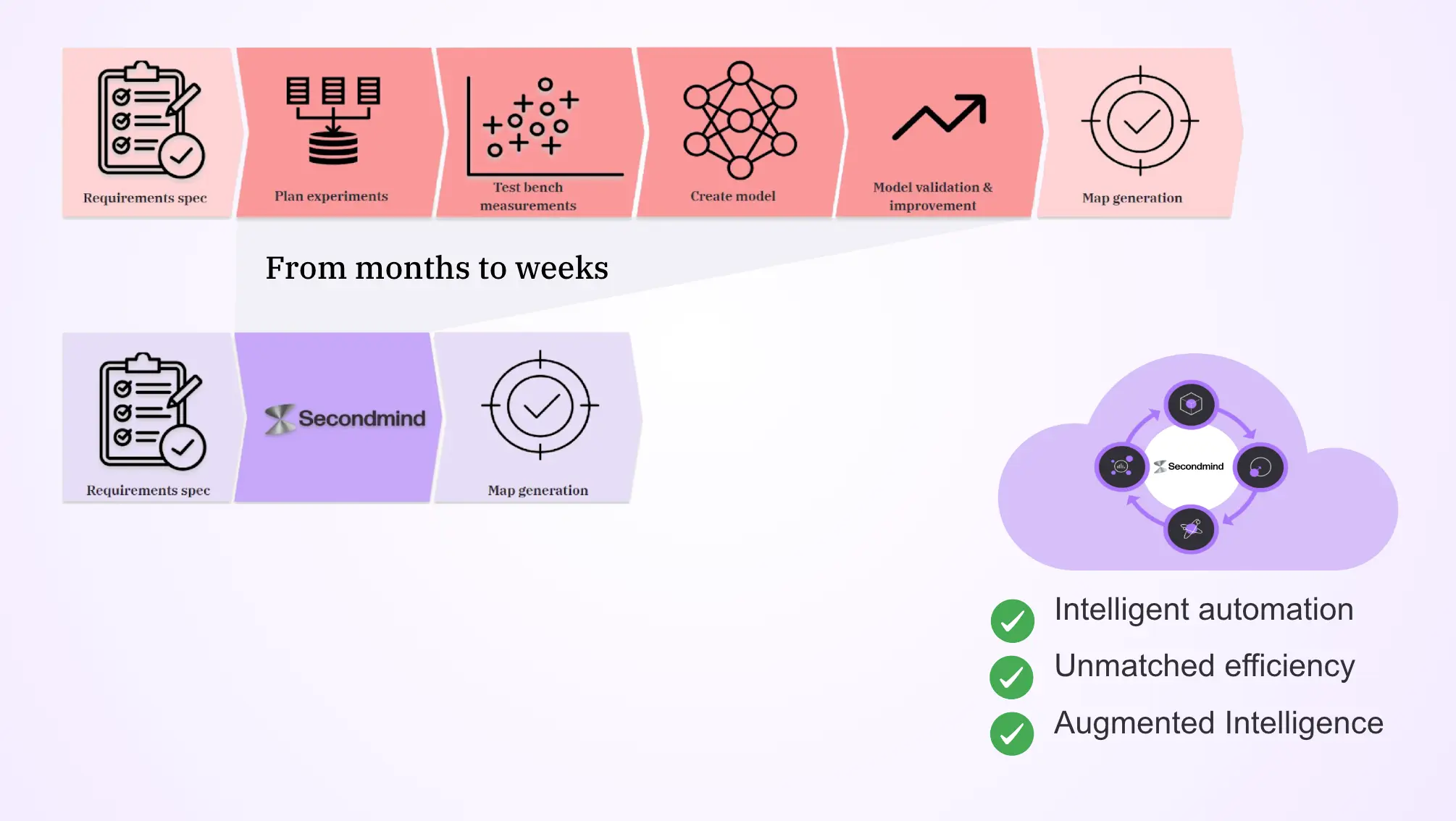

Engineers must create finely tuned calibration maps by efficiently balancing torque targets across all operational conditions. This involves a complex trade-off between multiple interconnected variables within a concise timeframe. Design of Experiments (DoE) explores relationships between input variables and responses. Still, its limitations include manual processes that require hands-on supervision and iterative adjustments, extending calibration cycles, and consuming human expertise in mundane work.

One example of the acute challenges facing calibration engineers is the Permanent Magnet Synchronous Motor (PMSM), used in EVs like the Nissan Leaf and Tesla Model 3. It is particularly challenging to calibrate due to the need for high-precision control over the motor’s thermal dynamics and the complex interplay of efficiency-critical parameters within a narrow tolerance range. As the magnet's heat during testing, torque performance decreases, which makes it difficult for the engineer to maintain the integrity and accuracy of the calibration process and ensure accurate vehicle range. With numerous measurements required at a consistent rotor temperature, there is lengthy cooling downtime between tests, significantly extending the process.

The Solution - Secondmind for Calibration

Secondmind for Calibration application for e-powertrain is a versatile solution that can optimize any electric motor system. The solution enables intelligent automation of the DoE process, which means engineers can create highly precise models in record time. Leveraging Secondmind Active Learning, the application focuses on only the most critical data points to significantly and swiftly improve model accuracy and reduce data requirements by up to 80%. Engineers see immediate time-savings as Secondmind requires just a small batch of sample data and the test plan to develop an initial model before starting an automated, iterative refinement loop that removes the need for manual planning of experiments.

With more accurate models from the outset and intelligent identification of which experiments will yield the most valuable data, unnecessary tests are minimized. As relevant data from each experiment sharpens model accuracy, the reduction in manual effort means engineers can move away from laborious manual tasks and instead focus their expertise on higher-value activities, such as tailored data contributions and model refinement.

In the PMSM example, Secondmind addresses the rotor temperature problem with an intelligent temperature compensation algorithm. In real-time, it automatically learns to account for the torque deterioration as a result of the heat in the motor across a range of operating conditions to significantly reduce the number of cooling iterations and enhance the data collection efficiency. By understanding and anticipating the thermal behavior of the PMSM, Secondmind empowers engineers to mitigate major transient effects, yielding faster measurement cycles without compromising data integrity.

This approach minimizes the need for lengthy cool-down periods between tests. It allows for continuous data acquisition, crucial for optimizing the motor's magnetic field effectiveness in various temperature scenarios. It further enables a multi-faceted optimization process that considers critical parameters, including motor speed, DC voltages, current amplitude, current phase angle, rotor temperature, and DC.

Secondmind merges physics-informed models with advanced machine learning, enabling highly precise predictions essential for advanced e-motor performance tuning. The application integrates the engineer’s deep domain knowledge with its state-of-the-art AI to create models that understand the complex interplay of factors affecting e-motor performance and quickly adapt to each motor's 'personality'.

This enhanced control and accuracy enables engineers to rapidly generate precise calibration maps through an agile process that leverages their deep system expertise. As a result, the typically arduous task of maintaining rotor temperature stability is transformed into a more manageable and markedly accelerated process.

The Impact - 80% less testbed occupancy

In intelligently automating the most labor-intensive calibration work, Secondmind for Calibration unlocks the potential for experienced engineers to focus their expertise on higher value electrification problem-solving, offering a substantial advantage over other DoE tools:

50% less time to generate higher-precision calibration maps due to the automation of labor-intensive calibration tasks, including testbench measurements, model creation, and validation.

80% less testbed occupancy to enhance calibration workflow efficiency

80% less data is needed to create high-precision models that learn

40% fewer costly prototypes are needed during testing

Secondmind facilitates precise and efficient calibration configurations for each distinctive e-motor system. This enables engineers to achieve greater accuracy with faster turnaround times and reduced data requirements, effectively vacating testbeds and reducing the dependence on early motor prototypes often bottlenecked by reservation conflicts. This acceleration in development helps bring new electric vehicles to market more quickly.

The Secondmind for Calibration application for e-powertrain recently won the Automotive Testing Technology International Award 2024 for Alternative Powertrain Test Innovation of the Year. For more details, read our press release here.