Producing high-precision calibration maps in half the time

Problem

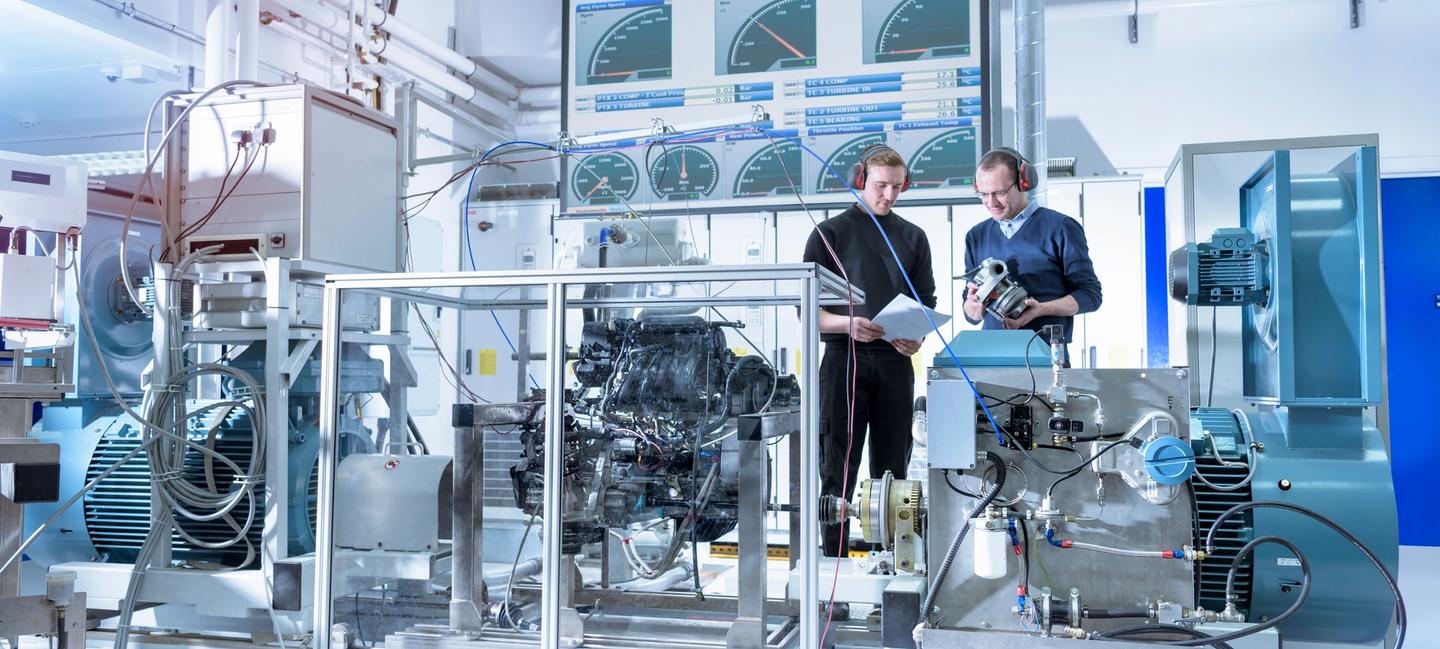

A leading automotive OEM approached Secondmind seeking to reduce time and data dependencies in their engine calibration process. The OEM had struggled to develop accurate models with existing tools, all of which lacked the ability to deliver acceptable results due to high dimensionality of parameters and unpredictable noise in the data. Current methods also forced the OEM to develop and combine many small models to represent their complex internal combustion engine (ICE) design, resulting in excessive and time-consuming model training and validation cycles.

Solution

Secondmind designed a solution that leveraged the Optimization Engine to:

- Observe and intelligently gather knowledge from the input and output data of the engine.

- Automatically modelling the noise and engine performance characteristics.

- Calculate profile optimum of the entire engine model.

Impact

- 2X efficiency gain in the calibration process through 80% reduction in data needs and 50% fewer observations.

- Reduction in the number of prototype engines needed for future programs and reduced time on the test bench while achieving increased accuracy.

- Reallocation of engineering subject matter experts to electrification projects.